In modern manufacturing, maintaining strict quality control is not just about compliance—it’s a defining factor for competitiveness. For industries such as automotive, aerospace, energy, and heavy machinery, verifying the reliability of metal components is crucial. That’s where metallurgical testing systems become indispensable.

What Is Metallurgical Testing?

Metallurgical testing involves analyzing metals and alloys to assess their microstructure, composition, and mechanical properties. This process ensures:

-

Structural integrity (absence of cracks, voids, or inclusions)

-

Conformity with recognized standards (ASTM, ISO, SAE)

-

Long-term performance and durability under stress

Testing methods can be destructive, involving sample removal, or non-destructive (NDT), allowing components to remain intact.

Why Metallurgical Testing Matters for Quality Control

Comprehensive metallurgical testing prevents component failures in critical applications like aircraft engines, automotive parts, pipelines, and structural steel. It helps manufacturers:

-

Avoid costly recalls and warranty issues

-

Ensure materials meet strength and hardness standards

-

Maintain compliance with customer and industry requirements

Without proper testing, companies risk operational delays, financial losses, and potential safety hazards.

Major Types of Metallurgical Testing

Manufacturers employ different testing systems depending on material and production needs:

1. Microstructural Analysis

Examines grain structure, inclusions, and heat treatment results using optical or scanning electron microscopes (SEM).

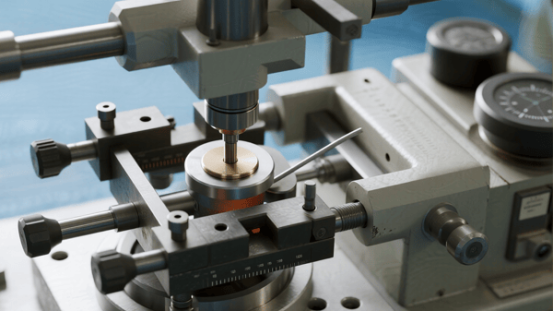

2. Hardness Testing

Assesses resistance to indentation using Rockwell, Brinell, or Vickers methods—ideal for evaluating treated or wear-resistant materials.

3. Tensile and Compression Testing

Measures a material’s strength and elongation, widely used for structural and automotive applications.

4. Impact Testing (Charpy, Izod)

Determines a metal’s toughness under sudden impact—essential for pipelines and heavy equipment.

5. Non-Destructive Testing (NDT)

-

Ultrasonic Testing (UT): Detects internal flaws without cutting samples.

-

Radiographic Testing (X-ray): Identifies subsurface cracks.

-

Magnetic Particle & Dye Penetrant: Reveals surface imperfections.

Choosing the Right Metallurgical Testing System

When investing in a testing solution, consider:

-

Material Type & Application: Steel, aluminum, titanium, and composites each require different testing approaches.

-

Testing Throughput: Automated systems are ideal for high-volume production.

-

Compliance Standards: Equipment should align with ASTM, ISO, and client requirements.

-

Integration: Advanced systems can connect with MES or ERP software for real-time monitoring.

-

Budget & Ownership Costs: Include maintenance, calibration, and operator training in total costs.

Features of Advanced Testing Systems

-

Automation: Robotic handling boosts consistency and speed.

-

Digital Reporting: Enables instant, traceable results.

-

Multi-Test Platforms: Combine hardness, tensile, and microstructural testing.

-

Data Connectivity: Supports Industry 4.0 and remote quality tracking.

Industries Relying on Metallurgical Testing

-

Automotive: Ensures fatigue resistance in engines and drivetrains.

-

Aerospace: Verifies structural integrity in turbine blades and landing gear.

-

Energy & Oil & Gas: Confirms pipeline and pressure vessel quality.

-

Construction & Heavy Machinery: Validates welds and structural components.

Benefits of Modern Testing Systems

-

Reduced material waste and rework

-

Faster production cycles through automation

-

Improved compliance and data accuracy

-

Lower operational costs and fewer recalls

Where to Purchase or Upgrade Systems

Leading suppliers offer:

-

Universal Testing Machines for tensile and compression analysis

-

Automated Hardness Testers for production lines

-

Portable NDT Devices for on-site inspections

Seek vendors that provide installation, training, calibration, and 24/7 technical support.

FAQs

What’s the difference between destructive and non-destructive testing?

Destructive testing damages or removes a sample, while NDT leaves the part intact.

Can metallurgical testing be automated?

Yes—modern systems feature robotics and integrated software for automated sample analysis.

How often should equipment be calibrated?

Follow manufacturer recommendations, typically every 6–12 months.

Does metallurgical testing improve compliance?

Absolutely. It verifies that products meet ASTM, ISO, and client-specific standards.

Conclusion

Metallurgical testing systems play a vital role in ensuring product safety, performance, and compliance in manufacturing. From hardness to NDT analysis, these systems help detect issues early and guarantee every part meets strict quality criteria. Investing in modern, automated, and data-connected systems enhances productivity, reduces costs, and supports a zero-defect production goal.